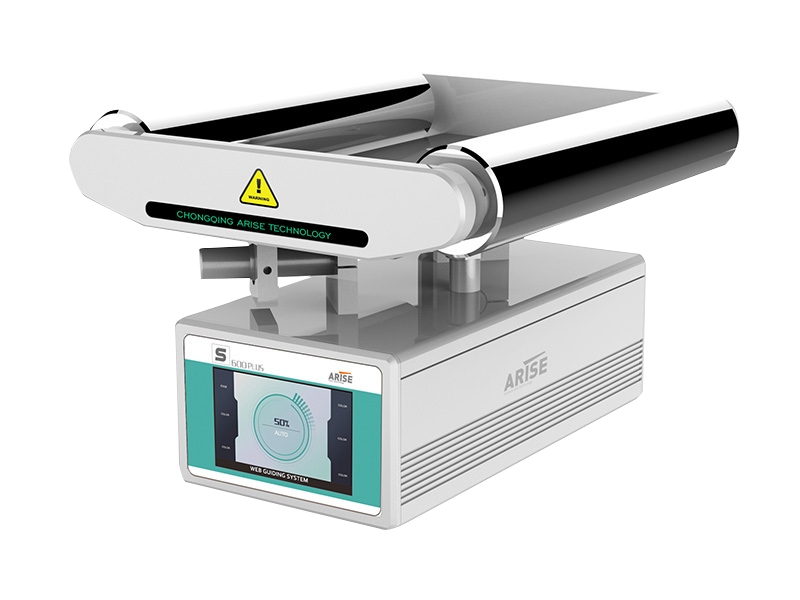

W500 all-in-one machine

Classification:

Web Guide System

Web Guide System

Keywords: coil correction tension, printing detection, tension system, still picture system

- Product Description

- Product Data

- Product Information

- Product Video

-

- Commodity name: W500 all-in-one machine

The coil is a long continuous material, such as paper, film, non-woven fabric, metal foil, textile, printed matter, etc. In the process of unwinding, technical processing, winding, etc., the position deviation of the coil may occur (because the coil itself is misplaced or caused by machine processing). Enruis W500 correction machine provides a solution to reduce the occurrence of such errors. The system always tracks the position of the coil in the production process and corrects the deviation in real time.

Working principle

The rectification system is operated by a closed loop controller. First, the sensor detects the coil edge or line, the system will automatically read the actual position deviation and then set the coil position and convert the deviation to an electronic signal sent to the controller. The controller calibration signal is output to the linear actuator. The linear actuator drives the correction according to the signal amplitude. The guide rail adjusts the coil to the set position. The present actuator drive signal provides precise control over the various coils in proportion to the coil deviation.

1 Track the edge of the coil and correct the uneven edge of the coil during winding.

2 Track the coil edge to keep the coating material at an equal distance from the coil edge.

3 According to the running speed of different materials, the correction speed can be adjusted to match.

4 supports three working methods: following the line, following the edge and centering.

5 Support photoelectric sensor, ultrasonic sensor, CCD image sensor.

6 sensor parameters automatic detection, most of the environment without calibration sensor.

7 Automatic stroke measurement without mechanical limit conversion.

8 ultra-high speed response, 500 microseconds (0.5 milliseconds).

9 Directly connected servo motor drives the ball screw.

10 support simplified Chinese, traditional Chinese, English three languages.

11 convenient humanized operation.

Please tell us your needs and we will get in touch with you as soon as possible!