Ultrasonic correction sensor A200

A200 is an ultrasonic correction sensor, using Fuji high-frequency ultrasonic probe, can detect the edge of paper, printing materials, films, transparent and ultra-transparent materials, etc., can be adapted to unwinding, winding, oven export and other environments, can not be used to detect mesh materials. It can be used normally under the interference of 30000 volt electrostatic environment and high power frequency converter.

View DetailsInfrared correction sensor A100

A100 is an infrared correction sensor, which can detect the edges of paper, printing film, film, non-woven fabric, gauze, screen window and other materials. It is most suitable for edge detection of materials with mesh. It cannot be used for ultra-transparent material detection. It can be used normally under the interference of 30000-volt electrostatic environment and high-power inverter.

View DetailsHigh temperature fiber optic sensor A300

A300 is a high-temperature optical fiber beam correction sensor, which can detect the edges of paper, printing film, translucent film, non-woven fabric, gauze, screen window, metal and other materials. It is most suitable for high-temperature material edge detection and can withstand up to 350 degrees. It can be used in 30000 volt electrostatic environment and high-power inverter interference environment.

View DetailsHigh Temperature Fiber Optic Sensor A300F

A300F is a high-temperature optical fiber reflection correction sensor, which can detect the edges of paper, printing film, translucent film, non-woven fabric, gauze, screen window, metal and other materials. It is most suitable for high-temperature material edge detection and can withstand up to 350 degrees. It can be used in 30000 volt electrostatic environment and high-power inverter interference environment.

View DetailsA400 is a CCD image sensor, using Panasonic CCD sensor and lens, 64-bit dual-core CPU, sampling time 0.1us, adaptive ambient light, specially used for tracking rubber edge and centering correction, real-time image display, full touch operation is easier.

View DetailsThe driver series adopts imported stepping motor, grinding ball screw, life-long maintenance-free, according to different needs, equipped with different motors, stroke, installation method, response speed, with left and right limit switches, can be adjusted externally. The driving speed is accelerated at the same time, the accuracy has been greatly improved. With limit switch, return switch, precision grinding ball screw, life-long maintenance-free, can be equipped with different stroke according to demand.The drive series adopts imported servo motor, grinding ball screw, life-long maintenance-free, according to different needs, equipped with different stroke, installation mode, response speed, and equipped with 1000 line incremental encoder, the driving speed is accelerated at the same time, the accuracy has been greatly improved. It can feedback the screw position in real time, has a return switch, and can identify the mechanical stroke with one key, precision grinding ball screw, life-long maintenance-free, and can be equipped with different strokes according to different needs.

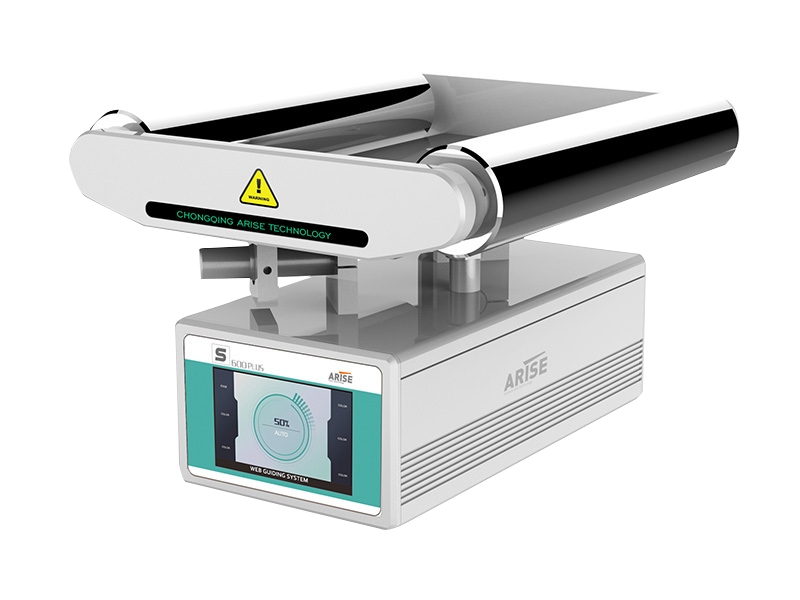

View DetailsW300, as a roller frame integrated machine, is a high-performance servo correction system operated by a full touch screen. It is specially used to track the edge, tracking line and contrast of materials. It is suitable for automatic control such as correction during coil travel. It calculates the offset of materials through ultrasonic, infrared and CCD sensor detection signals, and drives servo motor and coding feedback to accurately correct the offset materials according to the results. It is mainly used in paper, film and other industries.

View DetailsThe W280 all-in-one servo correction system is a high-precision and high-stability control system, which is specially used for the process correction of coil materials to ensure product quality and efficiency. Able to quickly detect corrections and deviations. Simple and easy to operate button panel, LED light dual display.The servo correction system of the W280Pro and tension all-in-one machine is a high-precision and high-stability control system, which is specially used for the process correction of the coil material to ensure the quality and efficiency of the product. Ability to quickly detect corrections and deviations. Simple and easy to operate button panel, LED light display, support control tension, open loop operation taper tension mode.

View DetailsOR-A, B and C are high-definition still picture observation systems. The system uses 5 million/10 million area array cameras to phase images. The images are magnified 25 times and are still clearly visible after processing. The shooting range is 55/100/200mm, and the maximum linear speed of the machine is 1200 m/min. The system can cruise automatically and is applied to printing, labeling and other industries.

View DetailsIncluding single guide roller/double guide roller/three guide roller frame correction. The correction roller frame is suitable for the winding and unwinding process of rubber and paper film. Various widths can be customized according to the model. Wide infrared ray, CCD sensor and full-width sensor can be selected according to different processes.

View Details