W300, as a roller frame integrated machine, is a high-performance servo correction system operated by a full touch screen. It is specially used to track the edge, tracking line and contrast of materials. It is suitable for automatic control such as correction during coil travel. It calculates the offset of materials through ultrasonic, infrared and CCD sensor detection signals, and drives servo motor and coding feedback to accurately correct the offset materials according to the results. It is mainly used in paper, film and other industries.

View DetailsThe W280 all-in-one servo correction system is a high-precision and high-stability control system, which is specially used for the process correction of coil materials to ensure product quality and efficiency. Able to quickly detect corrections and deviations. Simple and easy to operate button panel, LED light dual display.The servo correction system of the W280Pro and tension all-in-one machine is a high-precision and high-stability control system, which is specially used for the process correction of the coil material to ensure the quality and efficiency of the product. Ability to quickly detect corrections and deviations. Simple and easy to operate button panel, LED light display, support control tension, open loop operation taper tension mode.

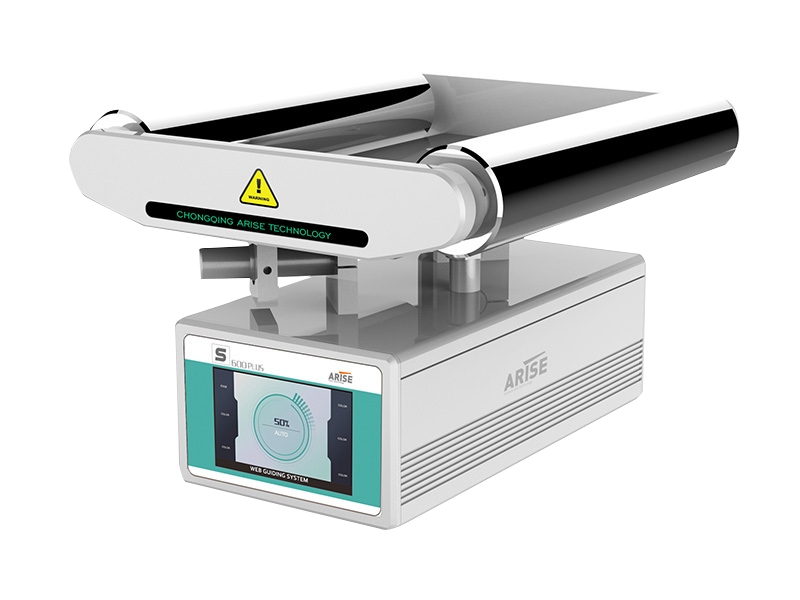

View DetailsIncluding single guide roller/double guide roller/three guide roller frame correction. The correction roller frame is suitable for the winding and unwinding process of rubber and paper film. Various widths can be customized according to the model. Wide infrared ray, CCD sensor and full-width sensor can be selected according to different processes.

View Details